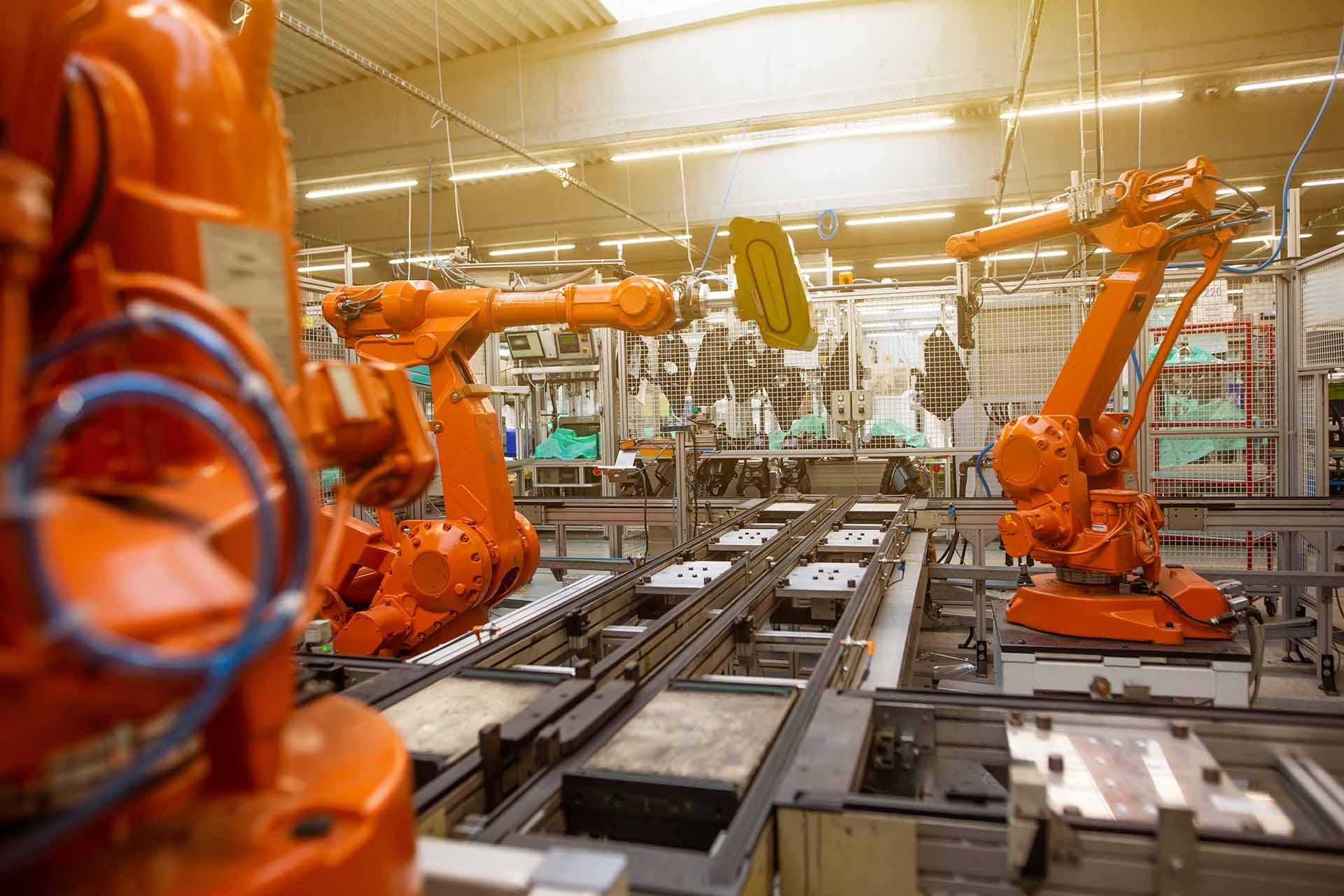

From prototype to series – in addition to the design and development of customer- and application-specific special solutions, we specialise in small to medium quantities. We are happy to advise you personally and individually, already in the design phase. With the help of our in-house metalworking department, we develop and manufacture custom and innovative tooling solutions for the production of your components.

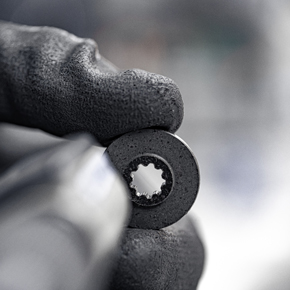

- Technology leader for monobloc rotors

- over 40 years of practical experience in material development and tool making

- unrivalled material characteristics & manufacturing tolerances

- High-performance mono rotors, composite components and patented duo rotors meet the highest application requirements

- DIN ISO9001 certified

- IHK research award winner for brake rotors with integrated sensor technology

Engineering –

customised solutions for your requirements.

Our competent team develops solutions tailored to your needs and supports you throughout the entire development process with many years of know-how in friction- and sliding applications.

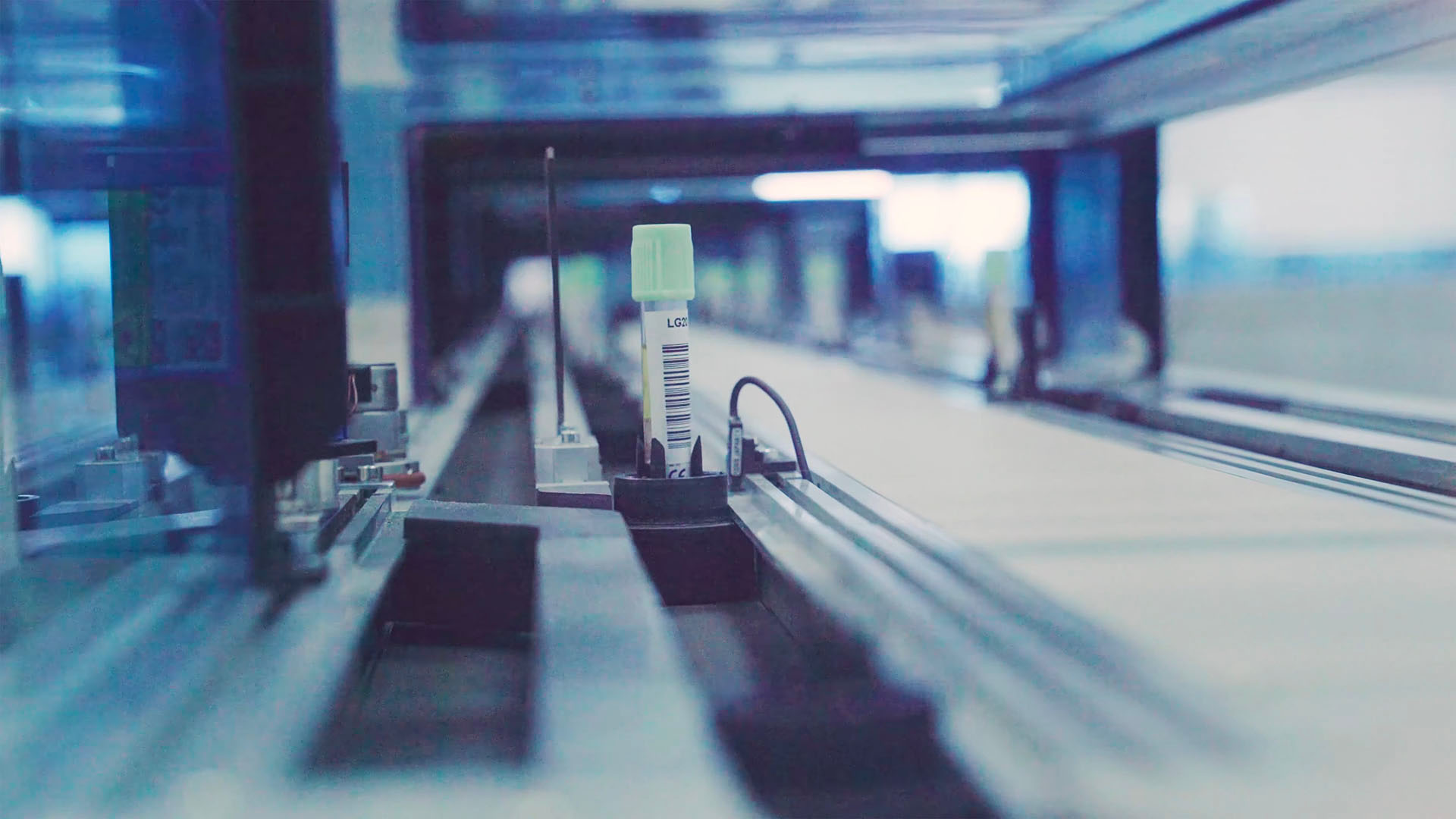

Production from start to finish

in Germany

From development to production: All our products are “Made in Germany”.

High-performance materials from REX

Heavily stressed materials must be continuously further developed. This is what we do, simultaneously taking into account the growing challenges of the industry, the progress of technology and the dynamic requirements of the markets. We increase your economic efficiency by going innovative ways.

Real people

We know that high-quality industrial products are subject to special challenges. For this reason, our engineers work day in, day out to support your projects efficiently and successfully.

The award of the IHK Research Transfer Prize for rotors with sensor technology highlights the expertise of the Friction and sliding linings department. Also, over 30 years of practical experience in the development of materials and the construction of tools demonstrates the high level and expertise that characterise the REX friction and sliding materials team.

Thanks to its special expertise in the development and manufacture of thermoset-based composite fibre materials, REX is able to produce particularly durable industrial friction and sliding linings that are characterised by high strength, low weight and long service life for brakes, clutches and special applications. – Engineered For Life.

REX accompanies your project from the sample phase through the production of prototypes to series introduction and support. Not only do we use our own standard materials, but we also develop custom materials for your project.

We do all this to not only provide you with the perfect product tailored to your needs, but also to provide you with the best possible service.