Product description

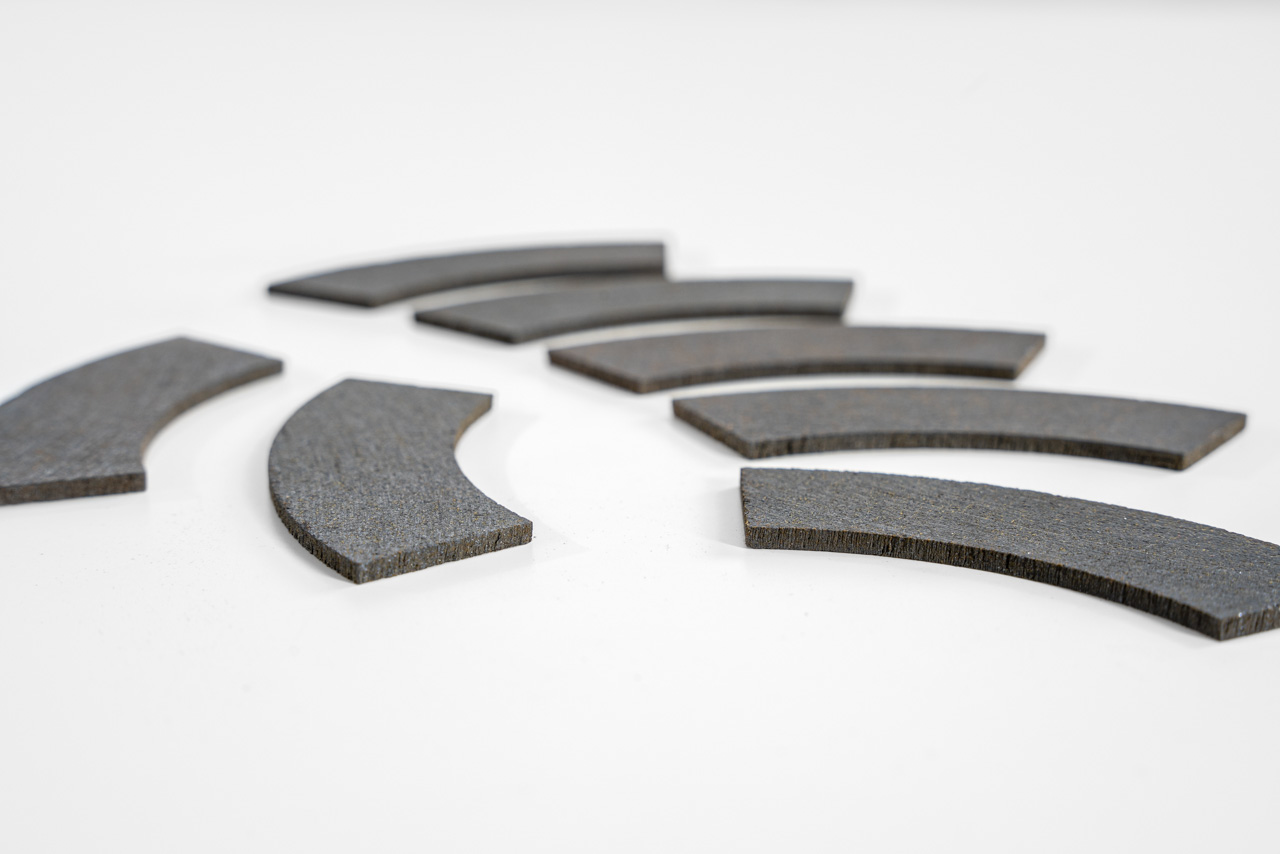

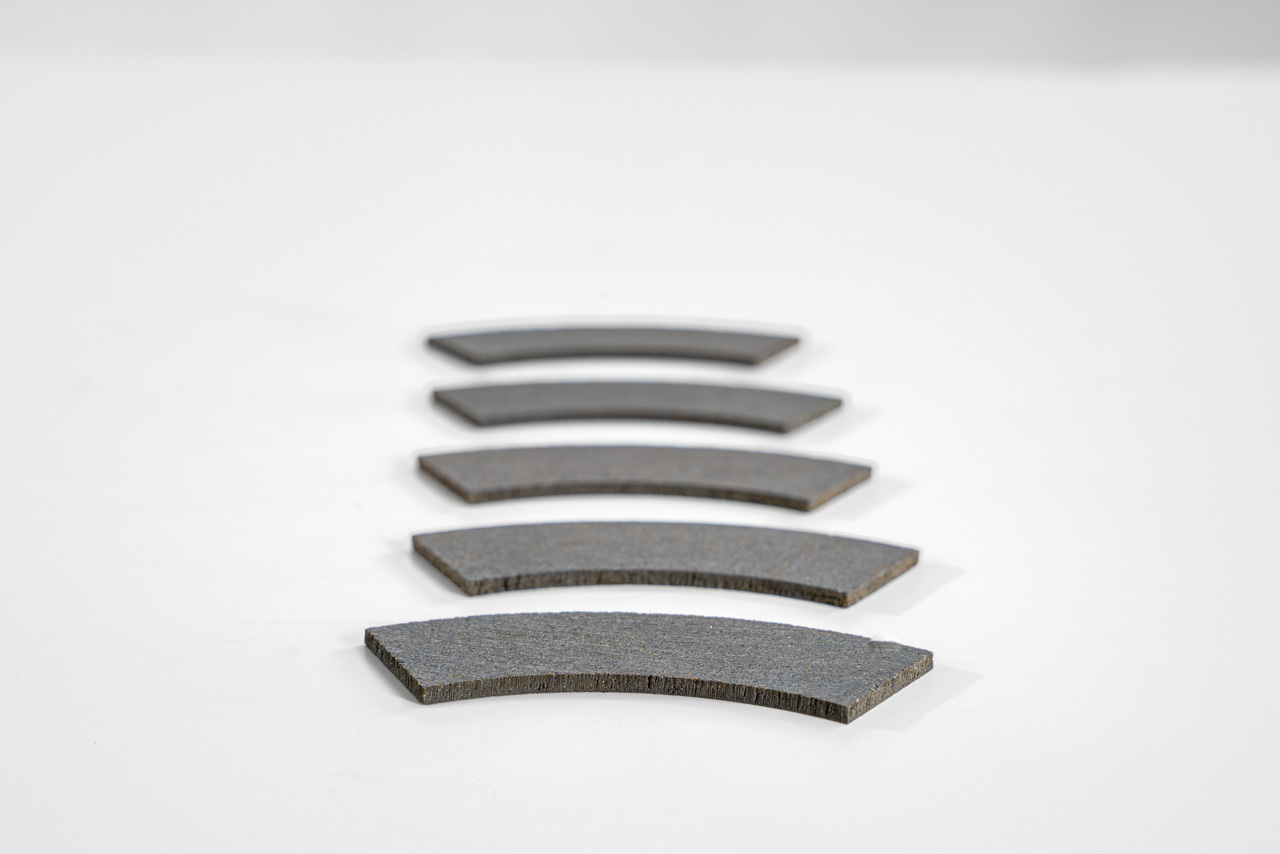

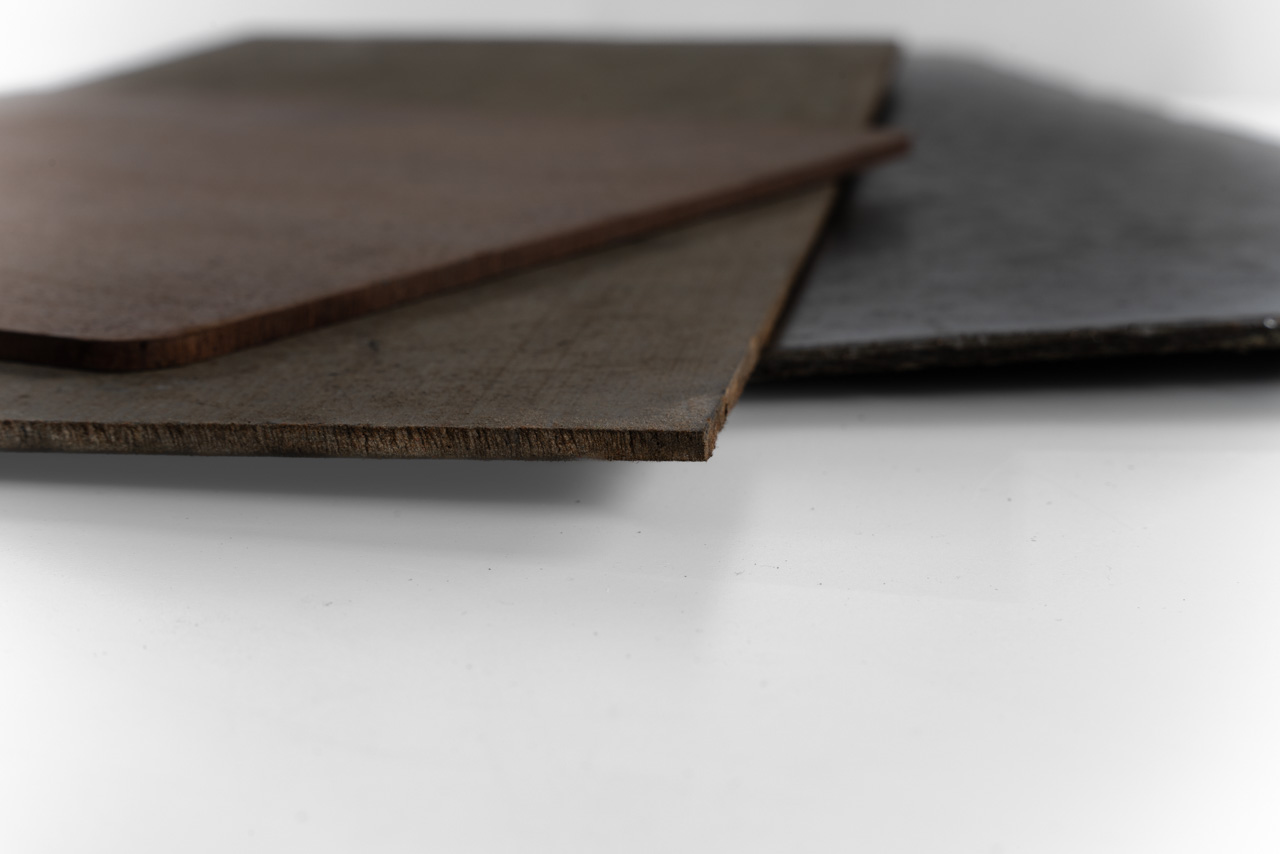

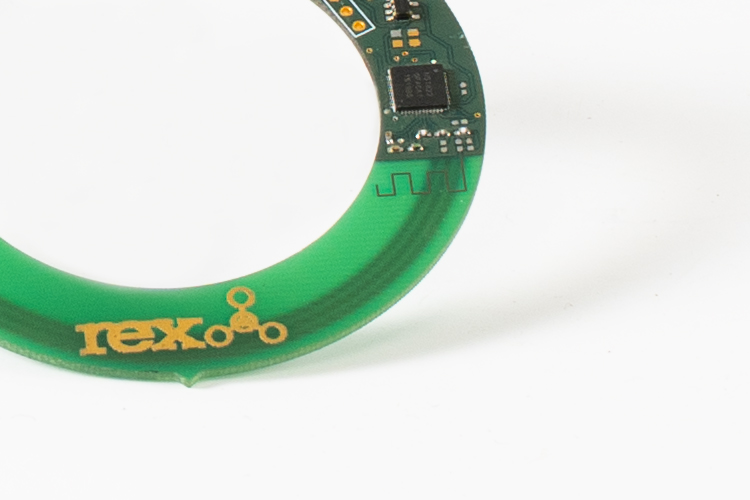

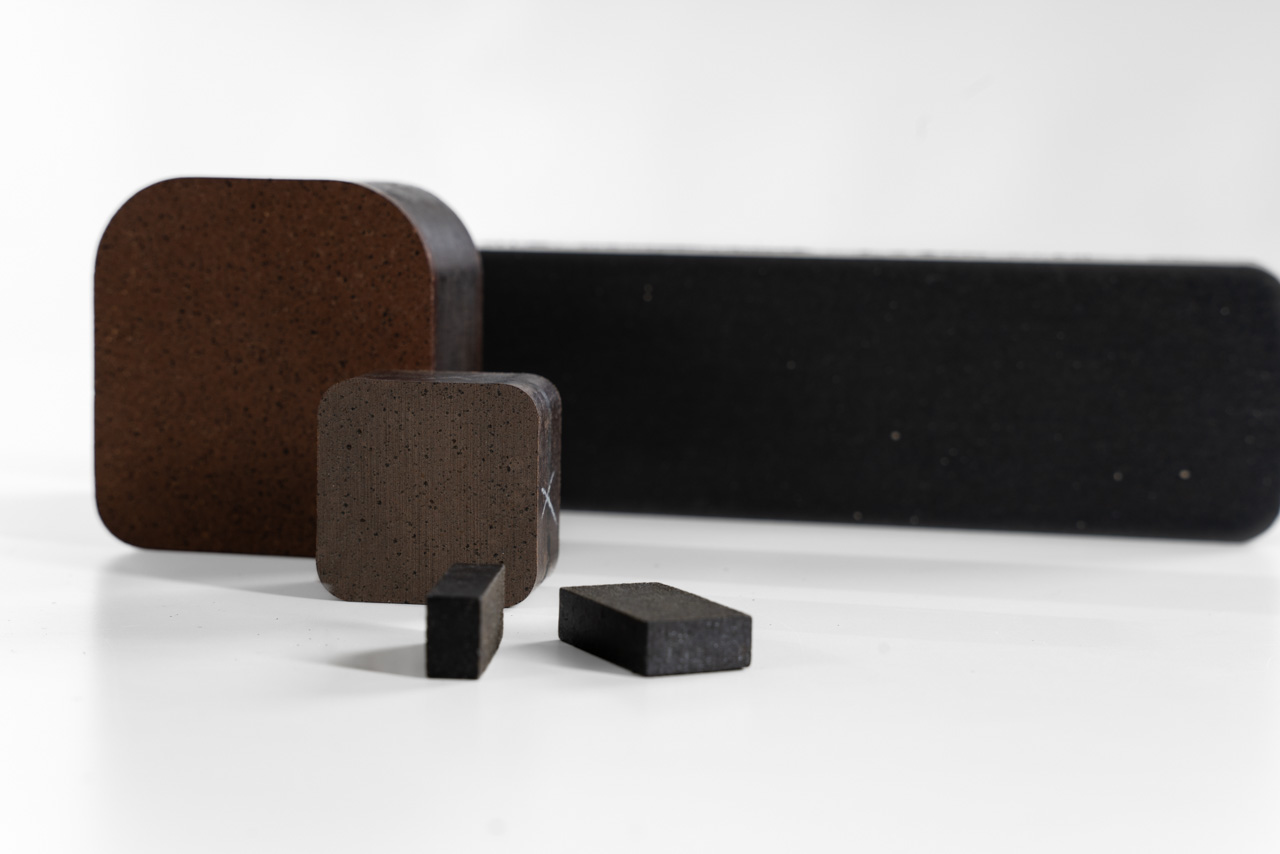

Custom rings made of friction and sliding materials for application to metal carriers.

Characteristics

- flexible selection of friction and sliding materials

- fast and cost-effective production

- no individual tooling required, therefore short development time and fast provision of prototypes and series parts

- rapid adaption to existing friction applications and model ranges

- Individual and application-specific advice on the use of the friction material

- Project support from sample phase to series introduction

- Tool and component design/planning

- REX in-house standard materials

- REX in-house material development for custom materials according to customer requirements

- Laboratory tests for friction, temperature, wear and strength behaviour

- FEM strength simulations and gear development

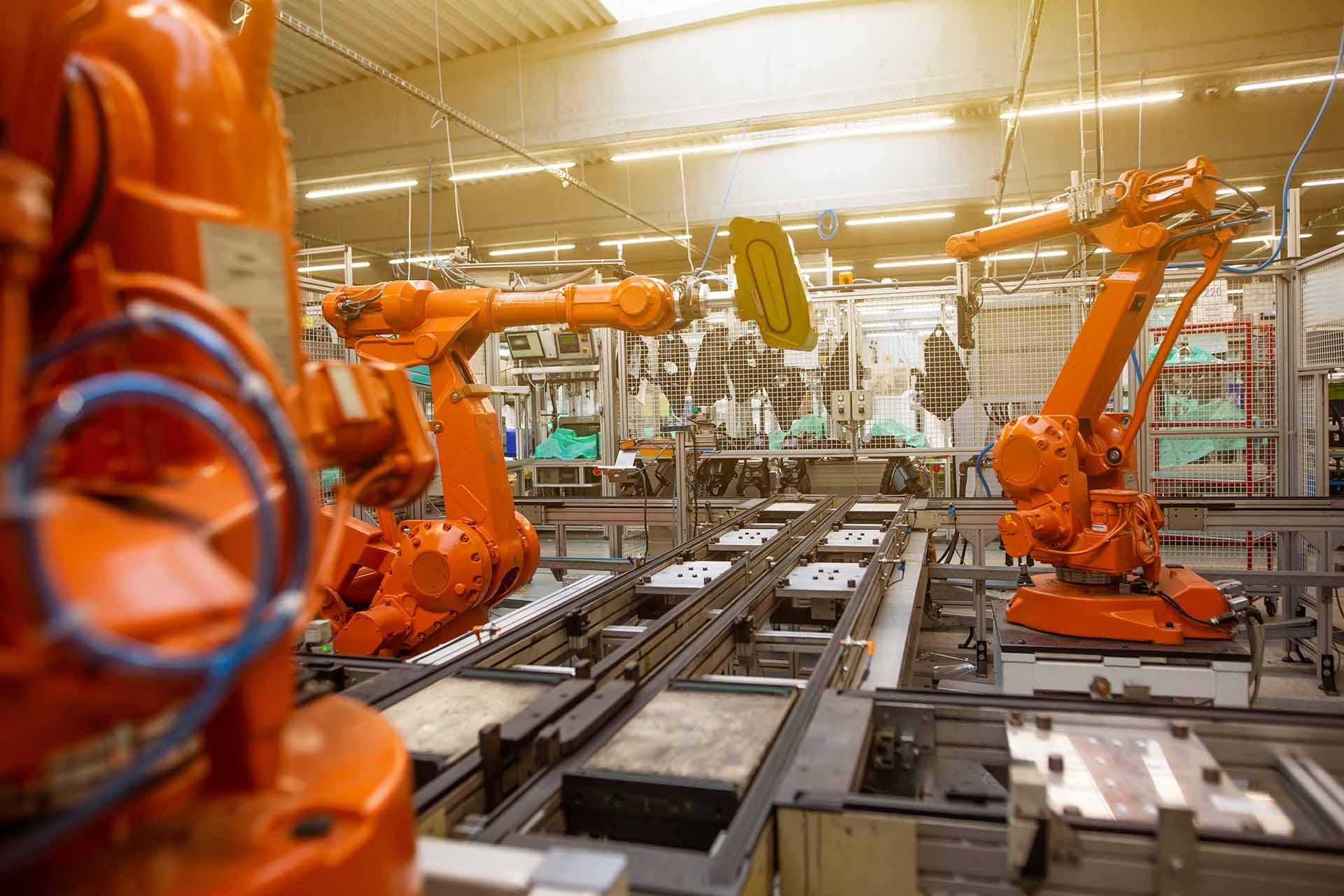

- Process development for series production and assembly

- Manufacturing of custom moulded parts

- Internal tool engineering and manufacturing

- Water jet cutting of 2D contours from friction lining plates

- Sawing of friction lining blanks

- Grinding of friction linings and metal parts

- Drilling

- Gluing of friction linings on various carrier materials

- CNC milling (5-axis milling technology) of friction lining parts in small and medium quantities

- CNC turning

- Marking (logo, QR code, data matrix, barcode, etc.)

- Manual and automated deburring of friction lining parts

- Assembly & fabrication

- Pressing technology

- Drive technology

- Mechanical engineering

- Mobility

- Robotics

- Lifting technology

- Positioning technology

- Actuating technology

R 529

(369.53 KB)

Download

R 535

(368.88 KB)

Download

R 675

(459.98 KB)

Download

R 686

(369.22 KB)

Download

R 721

(368.73 KB)

Download

R 722

(371.23 KB)

Download

R 724

(367.94 KB)

Download

R 725

(412.99 KB)

Download

R 726

(420.46 KB)

Download

R 727

(381.60 KB)

Download

R 728

(380.16 KB)

Download

R 730

(458.87 KB)

Download

R 731

(459.53 KB)

Download

R 732

(452.46 KB)

Download

Contact us!

Contact us!