Frequently asked questions

According to the Model Building Code (MBO) and the identical provisions of the state building codes, “§ 16 C Requirements for the use of CE-marked construction products: A construction product bearing the CE marking may be used if the declared performances comply with the requirements for such use laid down in this Act or on the basis of this Act. Sections 17 to 25(1) do not apply to construction products bearing the CE marking on the basis of Regulation (EU) No 305/2011.”

REX fire protection joint products are CE-marked construction products and have declarations of performance according to Regulation (EU) No. 305/2011. Thus, no proofs of usability such as “ABZ” or “ABP” or “proof in individual cases” are necessary. In the building inspection verification procedure, the CE mark with declaration of performance and assembly instructions is sufficient.

This is not possible from an building approval point of view, as the Rex approval only applies to joints between solid components. The steel beam would conduct the temperature of the fire to the side of the wall away from the fire.

T 30 or T 90 doors are components for which DIBT (German Institute for Structural Engineering) approval is required. If the approval holder for the doors has our joint cord tested simultaneously, then it is part of the system and may be used (e.g. for doors from Neuform-Türenwerke). If it is an approval where no joint cord was used, then the application can only be made with the approval of the approval holder, e.g. if he confirms a “non-substantial deviation” from the approval. This can usually be done if rock wool was used as the door frame seal.

According to European Technical Approval ETA 13/0269 for “Litaflex SM 30 + AF”, the use is only intended for building components with an apparent density of 2400 kg/m³ +/- 20 %. Aerated concrete is too light and therefore cannot be used, although the fire resistance duration of the component would be given. This is because we used components with 2400 kg/m³ in the approval test. That is why only this version was released to us. In the former building inspection certificate, the general civil engineering supervisory certificate, it was nevertheless possible to use lighter components than those tested, since all components that had the corresponding fire resistance class according to DIN 4102 were approved here. However, the ETA, as a European regulation agency, cannot refer to DIN standards (national regulations). Therefore, in our view, it is not permissible to use it unless there is an evaluation or an expert opinion for this application and the building permit is issued by way of an approval in the individual case.

The same applies to the “Litaflex-Vario” joint filling system.

For the joint filling system “Fugenschnur SG 300 N” we have carried out the tests for wall and ceiling with aerated concrete in 700 kg/m³. Therefore, all components with an apparent density of at least 700 kg/m³ and heavier are permitted here. Only for one special case – in the version with 2-layer design for joints with vertical shear stress – (Table B.3 of the ETA), components with a minimum gross density of 2400 kg/m³ are prescribed.

In connection with the filling of expansion and movement joints for reasons of preventive fire protection, the question of smoke density is often raised.

The term smoke-tight is only used in DIN 4102 in connection with tests on doors and gates.

For tests on components, which includes joints, there is the concept of smoke density in the sense of flammability. Therefore, during the fire test, a pilot flame is used in the area of the joint to check whether combustible, i.e. flammable, gases escape.

From these findings, it can be clearly concluded that in the event of fire, no flammable smoke gas escapes through properly (with our materials) filled expansion and movement joints. If one wants a “total” seal, one must also use permanently elastic grouting, which, according to our test reports, has no negative impact on fire resistance behaviour. However, since it is usually not known from which side of the component the fire is coming, sealing on both sides is recommended.

No! Joint cord and Litaflex joint fillings must be protected from water ingress on site before installation and in the joint. In the European Technical Assessment, under “General Aspects”, the “Use Category Type Y1 and Y2” is : “…for application …. but without exposure to rain.” From this it can be concluded without a doubt that the product must be protected from moisture.

Litaflex blocks and Litafelx folding elements may also be used in fire walls. They are nationally classified as non-combustible class A1 according to DIN 4102. A detailed justification can be found in our technical information here.

SG 300 and SG 300 N joint cord may be installed in fire walls. This does not reduce the fire resistance class F 90-A or EI 90 of the wall. Further information can be found in the expert opinion, see here.

Joint cord SG 300 and SG 300 N may also be installed together with elastic sealant in F 90 walls and in fire walls. This does not reduce the fire resistance class F 90-A or EI 90 of the wall. Further information on this can also be found in the expert opinion on this, see here.

On page 7 it states “An additional permanently elastic sealing, e.g. with PU, silicone or acrylic sealing, has no negative influence on the fire resistance class of the component”.

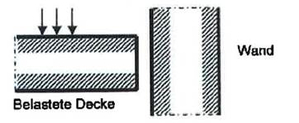

We speak of shear joints when 2 components are axially displaced relative to one another. The ceiling loaded from above “shears” along the wall. For this situation we have an EI 90 verification with joint cord.

The use of both joint cords is permissible, according to building law it is a connection between a ceiling and a wall without shear stress.

The cords are also permissible in combination with sound insulation bearings on the stringers of the stairs, if the sound insulation element is cut back in the area of the cords.