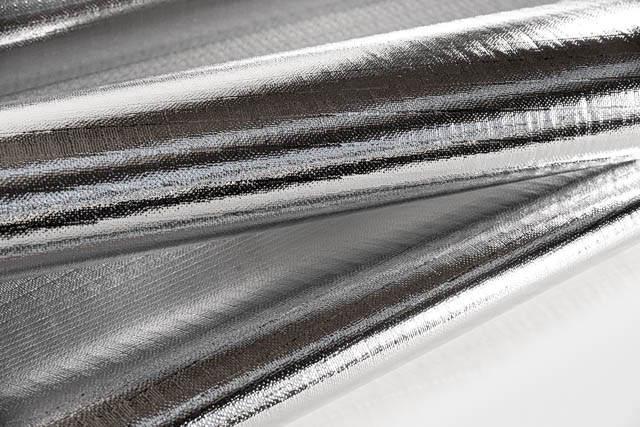

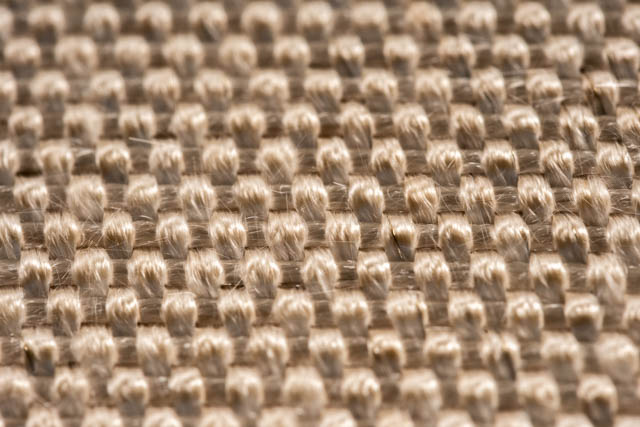

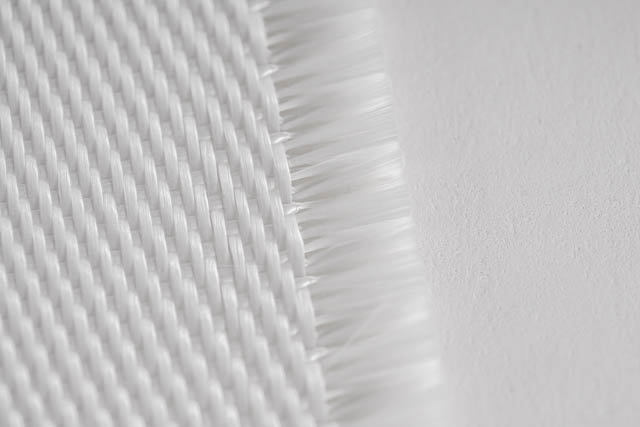

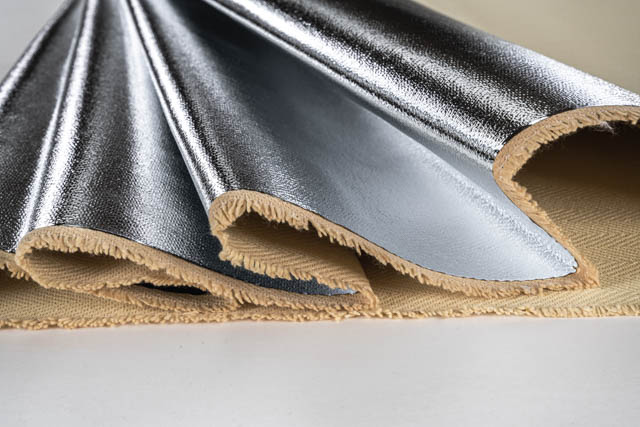

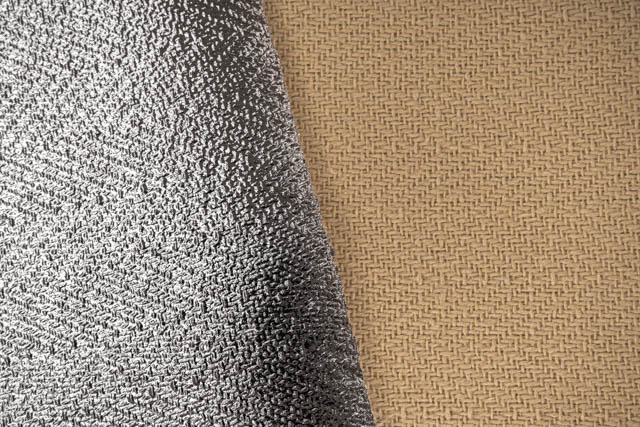

Using squeegee or transfer coatings, our fabrics can be optimised on one or both sides with a functional surface to meet customer and application requirements. A variety of coating materials such as PVA, PU or silicone are available. We offer our coated fabrics with different overlays, in various colours as well as with confirmations of compliance with flame retardant standards and food fastness.

PVA/PU:

- application temperature 180–200 °C

- improved fabrication properties

- improved slippage resistance

- improved mechanical properties

- media resistance

- single and double-sided colour variations possible

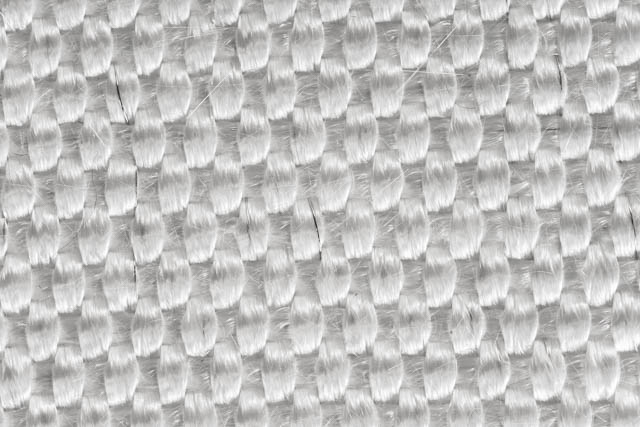

silicone:

- application temperature up to 250 °C, special silicones up to 300 °C

- weather resistant

- good light and UV resistance

- hydro- and oleophobic

- good abrasion and cut resistance

- food-safe version on request

- colour variations possible

- does not melt

Type Order Weight[g/m²] Thickness [mm] Width [mm] Color Binding

PU-g1

TG 200 L one-sided 215 0,2 1040 grey Canvas

TG 440 KK one-sided 450 0,4 1000, 1200 grey Cross twill

TG 550 Niro L one-sided 560 0,6 1200 grey Canvas

TG 660 A one-sided 670 0,7 1000, 1200,1300, 2000 grey Atlas

TG 1000 L one-sided 1030 1,3 1000 grey Canvas

PU-g2

TG 440 KK double-sided 480 0,4 1000, 1500 grey Cross twill

TG 660 A double-sided 700 0,75 1000, 1500 grey Atlas

TG 800 Karo double-sided 830 0,9 1040 grey Karo

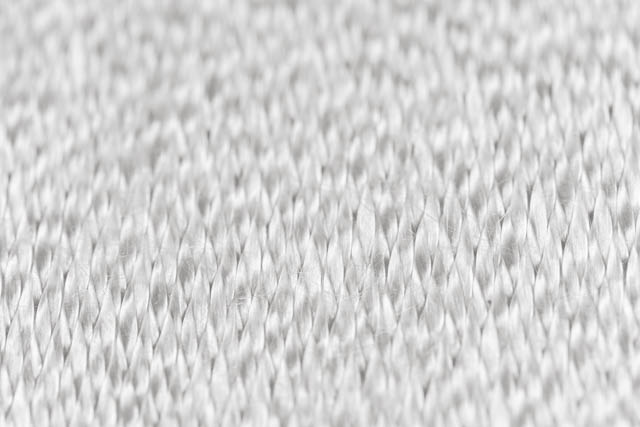

PU-w1

TG 440 KK one-sided 440 0,45 1000, 1200 white Cross twill

TG 660 A one-sided 670 0,7 1000, 1200 white Atlas

TG 940 KK one-sided 960 1,2 1000 white Cross twill

TG 1000 L one-sided 1030 1,3 1000 white Canvas

Silicone TG 440 KK one-sided 60 g/m² 480 0,5 1550 grey Cross twill

TG 440 KK one-sided 80 g/m² 500 0,5 1000, 1200, 1270, 1500 grey, black Cross twill

TG 440 KK double-sided 80/60 g/m² 560 0,5 1000, 1200 grey Cross twill

TG 660 A one-sided 100 g/m² 760 0,7 1000, 1200 grey Atlas

TG 660 A double-sided 170 g/m² 1000 0,7 1000 grey Atlas

TG 800 A double-sided 130g/m² 1060 0,8 1000 grey Atlas

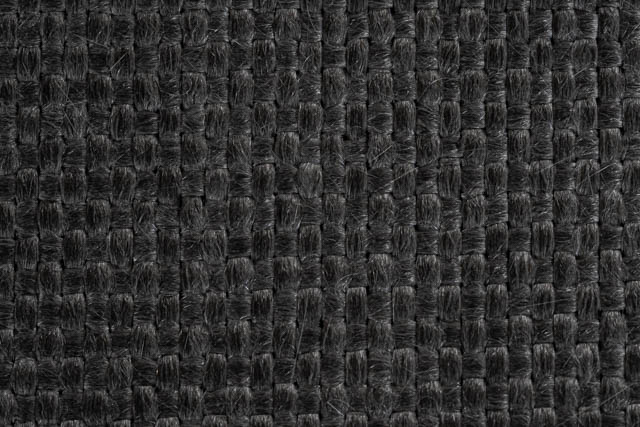

PTFE TG 440 KK one-sided 560 0,4 1524 grey Cross twill

TG 440 KK one-sided 560 0,4 1524 black Cross twill

Other variants on request

Material: E-glass fabric

Type Equipment MED Module B + D EN 45545-2:2020

Railroad applications - Fire protection in rolling stock

Part 2: Fire behavior requirements for materials and components

TG 440g/m² PU-g1 X

TG 440g/m² PU-w1 X

TG 440g/m² SiF grp 1/80 X

TG 660g/m² PU-g1 X

TG 660g/m² PU-w1 X

TG 940g/m² PU-w1 X

Roll goods in various standard run lengths. Customer-specific adaptations are possible after consultation.

For high temperature insulation and component protection

Coatings that only serve to provide slippage resistance during processing, steam off during initial use due to their low temperature resistance from 160 °C upwards.

Silicone can become brittle under permanent high temperature influence and/or short-term influence above the recommended application temperature.