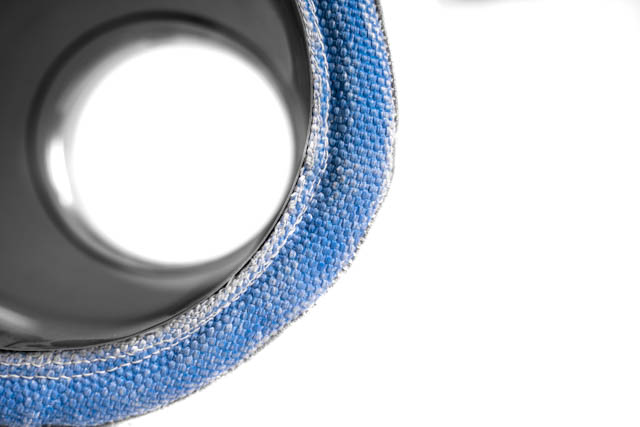

Insulating sleeves for heating zones of plastic processing machines are primarily used to save heating energy. This results in further benefits such as an increase in the machine’s performance, new competitive advantages due to more favourable production possibilities, and a cooler surface temperature for greater occupational safety. The insulating sleeves are made individually regardless of the machine type. The special segmental design allows precise cutouts for electrical connections and sensor inputs. The high quality and durability is guaranteed by the exclusive use of tested materials.

REX insulating sleeves have been tested by a neutral institute, the Kunststoffzentrum in Leipzig, for their function in terms of heating energy savings. In tests with injection moulding machines, heating energy savings of up to 50% were determined, depending on the polymer.

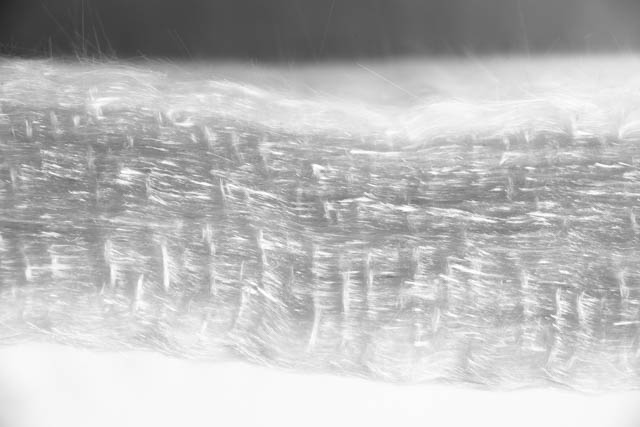

- high temperature resistant up to 1000 °C

- non-combustible

- vibration resistant

- high insulation value

- splash-proof

- easy to assemble and disassemble

- maximum individuality in fabrication

- highest quality and durability from REX

- 100% customisable and accuracy of fit thanks to innovative Shining 3D scanner

- up to 50% cost savings due to maximum insulation

- extremely short amortisation period

- pleasant ambient atmosphere and highest occupational safety

- universally applicable in all insulation areas in industry

- individual and application-specific advice on the use of insulating sleeves and textile molded parts

- project support from sample phase to customised production & assembly

- precise production thanks to innovative Shining 3D scanner

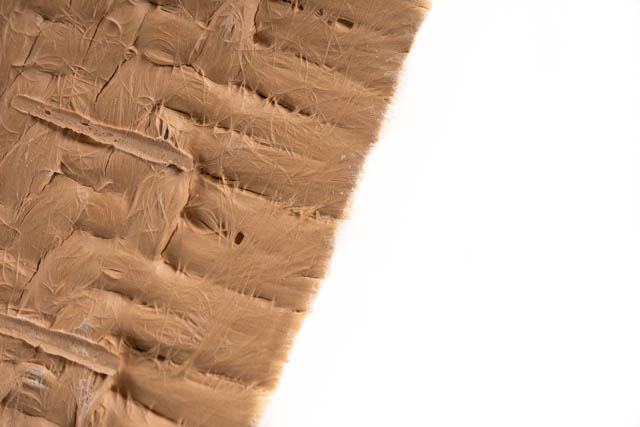

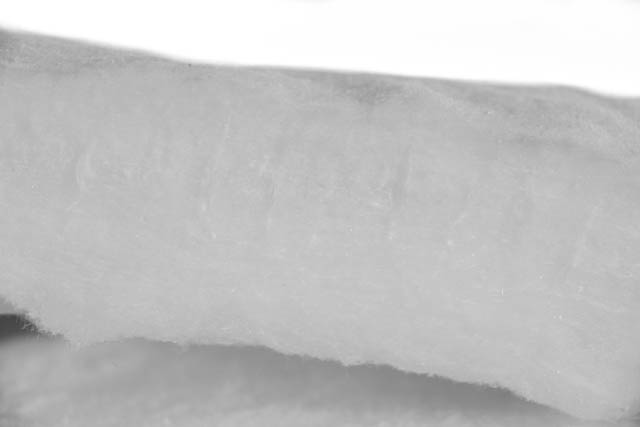

- wide range of standard & high-performance materials

- REX’s own material development for custom materials and technical textiles according to customer requirements

- quality management with proven effectiveness (test reports from KUZ Leipzig)

- laboratory tests for temperature and insulation behaviour

- certification according to ISO 9001:2015

- process development for series production and assembly

- technical textile as the basis of processing

- made to measure

- application of velcro fasteners

- labelling/marking (logo, QR code, data matrix, barcode, etc.)

- special production for optimised maintenance

Standard:

The sleeve is completely removed for maintenance work or to allow the machine to cool down when the plastic is changed.

2-piece with retaining strap:

Additional retaining straps allow fast, two-stage disassembly of the insulation for maintenance and setup work. While part of the sleave remains fixed to the machine with the retaining straps, the upper part can be removed quickly and easily using Velcro.

1-piece with retaining strap (hinged):

The internal retaining straps allow the insulating sleeve to be opened without having to perform complete disassembly. This means that maintenance work and cooling phases can be performed quickly and easily.

| Branch | Usage | Solution |

| Manufacturing Industry | Heating zones of plastics processing machines or injection molding machines as well as all other pipelines | Insulation and thermal insulation of the pipes |

| Mechanical Engineering | Use in energy-intensive production plants where hot media are used. | Keeping the temperature of heating elements, pipes constant. Insulate containers |

| Power plant construction Biogas plants Combined heat and power plant | Gas turbines and pipelines must be insulated to protect against burns. | Insulation of turbine housings and attachments |

| Construction machinery | Vehicles or equipment with limited space for the drive technology, engine, etc. | Insulation & heat protection of expansion joints, turbochargers or exhaust pipes |

| Emergency generators | Stationary emergency generators with combustion engine | Insulation of exhaust pipes and components |

HKT Hienz Kunststofftechnik measurement results in 92224 Amberg.

The measurements were carried out on an Engel 400 ton injection moulding machine with a cylinder Ø of 60 mm, once with and once without insulating sleeves.

The material used was an ABS/PC.

Engel 400 ton injection moulding machine without insulation

Energy consumption approx. 4 KW, power consumption 100% (in automatic mode)

SGM Engel 400 ton injection moulding machine with insulation

Energy consumption approx. 2.5 KW, power consumption 62.5% (in automatic mode)

Savings of 37.5%

This does not include the savings during the heating phases.

-

UP TO50 %LESS HEATING ENERGY COSTS

-

UP TO1000 °CTEMPERATURE RESISTANCE

-

CERTIFICATIONISO 9001 :2015QUALITY MANAGEMENT SYSTEM

Co-Division Manager/Sales Manager

HT Insulation/Fire Protection

Sales + Application technology

HT Insulation/Fire protection