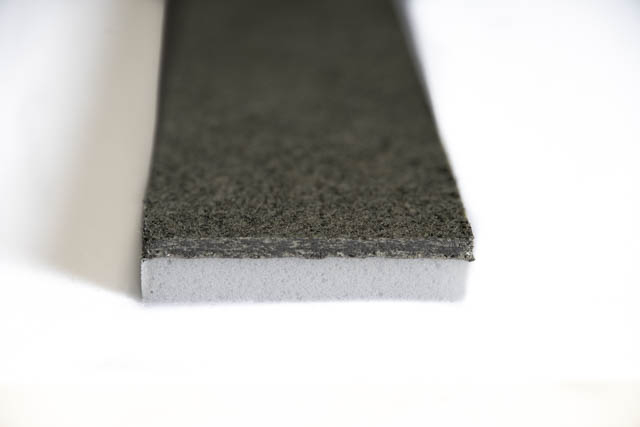

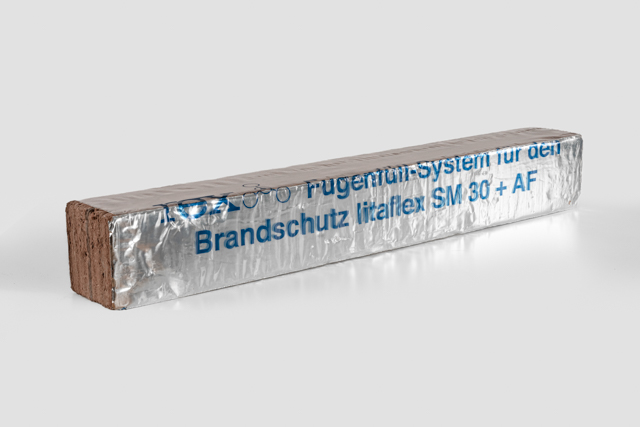

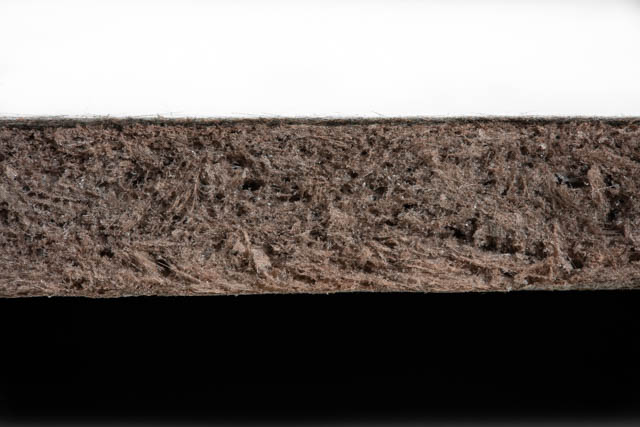

REX joint filling systems are non-combustible joint fillers and fire protection seals according to DIN 4102-A1 or EN 13501-1. Depending on the structure, they prevent the permissible temperatures from being exceeded for 90 to 120 minutes aand prevent the passage of fire and combustible gases.

Additional sealants to protect against dirt, water and destruction do not affect the fire behaviour. Simple assembly without complex tools.

- for joints from 10 to 200 mm joint width

- for movement and/or expansion joints under the influence of fire, temperature, movement

- joint seal possible in connection with elastic sealing compound or with joint tape

- loadable construction joint in connection with expansion profile

- suitable for the following connections:

- Ceiling / Ceiling

- Ceiling / Wall

- Wall / Wall

- Wall / Support

- Ceiling / Joist

- A1 non-combustible according to DIN 4102 Part 1 or EN 13501-1

- tested for use up to 1050 °C (F120)

- highly elastic, dimensionally stable for large joint widths

- can be laid in strips or blocks, fast processing

- compensation of joint tolerances due to component irregularities

- toxicologically harmless

- classification achieved without the use of elastic sealants

- elastic joint sealants do not affect resistance to fire

Combustible joint fillings in the joint space not filled by the Litaflex SM 30 may remain in the joint. This means that combustible storage material located in the joint must only be removed to the extent that space is required for the installation of the folding element or joint block.

Additional sealants to protect against dirt, water and destruction do not affect the fire behaviour. Simple assembly without complex tools.

- before installation, check that all marginal conditions (e.g. type and thickness of space-enclosing components, width of joints) comply with ETA-13/0269 provisions.

- Care must be taken to ensure that the material is stored securely without damage and weathering prior to installation.

- Litaflex elements or blocks are best cut to the required length with an untoothed insulation knife.

- the elements and blocks are laid butt to butt. The abutting surface is then generously coated with Litaflex adhesive 800.

- keep contact surfaces of joint flanks for primer and sealants free of Litaflex adhesive!

(Otherwise the adhesion of the sealant cannot be guaranteed and cracks will occur) - joints with a width greater than 150 mm must always be secured and horizontal ceiling joints must, if necessary, be secured against stepping on, damage and water ingress by means of suitable protective measures.

Table for wall F90 or EI 90-V-X-F-W 10 – 50

| Joints- width | Wall thickness | Element- lenght | Element- width | Element- thickness |

| 10 - 15 mm | ≥ 100 mm | 1.000 mm | 200 mm | 10 mm |

| 15 - 20 mm | ≥ 100 mm | 1.000 mm | 200 mm | 15 mm |

| 20 - 30 mm | ≥ 100 mm | 1.000 mm | 200 mm | 20 mm |

| 30 - 40 mm | ≥ 100 mm | 1.000 mm | 200 mm | 25 mm |

| 40 - 45 mm | ≥ 100 mm | 1.000 mm | 200 mm | 30 mm |

| 45 - 50 mm | ≥ 100 mm | 1.000 mm | 200 mm | 35 mm |

Table for wall F120 and ceiling F90 and F120

or EI 120-V-X-F-W 10 – 50 and EI 120-H-X-F-W 10 to 50

| Joints- width | Wall thickness | Element- length | Element- width | Element- thickness |

| 10 - 15 mm | ≥ 150 mm | 1.000 mm | 250 mm | 10 mm |

| 15 - 20 mm | ≥ 150 mm | 1.000 mm | 250 mm | 15 mm |

| 20 - 30 mm | ≥ 150 mm | 1.000 mm | 250 mm | 20 mm |

| 30 - 40 mm | ≥ 150 mm | 1.000 mm | 250 mm | 25 mm |

| 40 - 45 mm | ≥ 150 mm | 1.000 mm | 250 mm | 30 mm |

| 45 - 50 mm | ≥ 150 mm | 1.000 mm | 250 mm | 35 mm |

Table for wall F90 or EI 90-V-X-F-W 50 – 200

| Joint- width in mm | Wall thickness | Element length in mm | Block- width in mm | Block thickness / filling depth in mm |

| 50 - 60 | ≥ 100 mm | 1000 | 75 | 90 |

| 60 - 70 | " | 85 | 90 | |

| 70 - 80 | " | 95 | 90 | |

| 80 - 90 | " | 110 | 90 | |

| 90 - 100 | " | 120 | 90 | |

| 100 - 110 | ≥ 150 mm | " | 130 | 140 |

| 110 - 120 | " | 145 | 140 | |

| 120 - 130 | " | 155 | 140 | |

| 130 - 140 | " | 170 | 140 | |

| 140 - 150 | " | 180 | 140 | |

| 150 - 160 | " | 190 | 140 | |

| 160 - 170 | " | 205 | 140 | |

| 170 - 180 | " | 215 | 140 | |

| 180 - 190 | " | 225 | 140 | |

| 190 - 200 | " | 230 | 140 |

Table for wall F120 and ceiling F90 and F120

or EI 120-V(H)-X-F-W 50 – 200

| Joints- width | Wall thickness | Element- length | Block- width in mm | Block thickness / Filling depth |

| 50 - 60 | ≥ 150 mm | 1000 | 75 | 140 |

| 60 - 70 | " | 85 | 140 | |

| 70 - 80 | " | 95 | 140 | |

| 80 - 90 | " | 110 | 140 | |

| 90 - 100 | " | 120 | 140 | |

| 100 - 110 | " | 130 | 140 | |

| 110 - 120 | ≥ 200 mm | " | 145 | 190 |

| 120 - 130 | " | 155 | 190 | |

| 130 - 140 | " | 170 | 190 | |

| 140 - 150 | " | 180 | 190 | |

| 150 - 160 | " | 190 | 190 | |

| 160 - 170 | " | 205 | 190 | |

| 170 - 180 | " | 215 | 190 | |

| 180 - 190 | " | 225 | 190 | |

| 190 - 200 | " | 230 | 190 |

e.g.

EI 120-V-X-F-W 10 to 55

or

EI 120-H-M040-F-W 50

| E | Room closure |

| I | Thermal insulation |

| 120 | Fire resistance duration in minutes |

| V | vertical supporting structure (wall joint) |

| H | horizontal supporting structure (ceiling joint) |

| X | Mobility: no movement (max. permissible lateral movement 7.4 %) |

| M | Mobility: maximum permissible movement in % |

| F | Butt joint created on site |

| W | Range of joint widths from/to in mm |

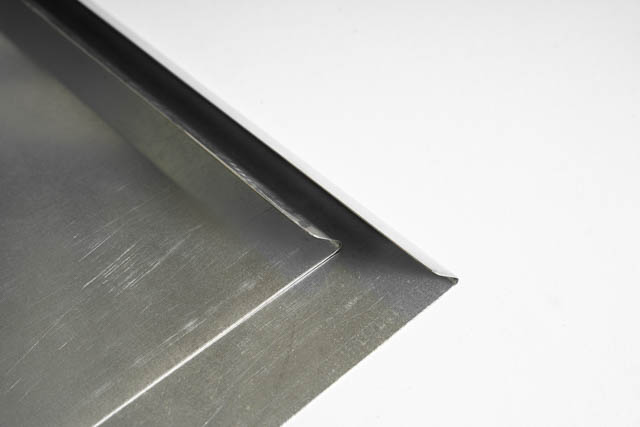

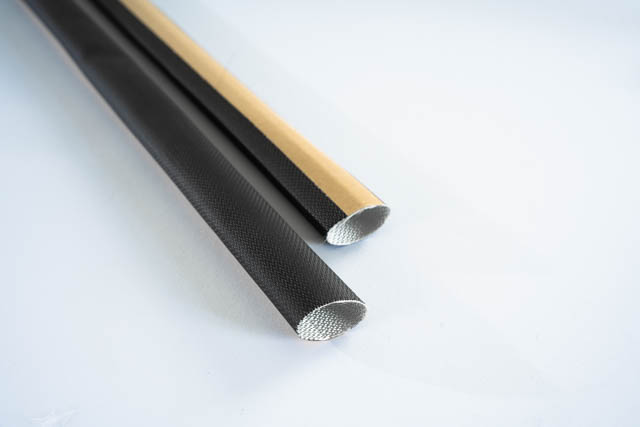

Insertion plate installation aid

Sheet steel 0.75 mm, galvanised, with rounded corners, length 1 metre

Order number: 580 000 000

-

UP TO200 mmJOINT WIDTH

-

PREVENTS FIRE PASSAGE FOR UP TO120 minFIRE PASSAGE

-

DEPLOYABLE UP TO1050 °CF120

Co-Bereichsleiter/Leiter Vertrieb

HT-Dämmung/Brandschutz

Sales + Application technology

HT Insulation/Fire protection